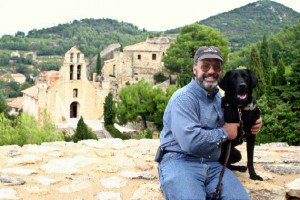

A few weeks back, I had the opportunity to visit the workshop where La Cornue stoves are manufactured. La Cornue is the French brand for luxurious kitchen ranges, and is this year celebrating the 110th anniversary of its famous vaulted oven, first created in 1908.

I’ve always loved factory tours, and this one lived up to my expectations. I’ve been dreaming of La Cornue ranges for a long time, and I was glad to confirm that the perception I had — that of a luxurious artisan brand — was indeed reflected in the high standards maintained in every step of production.

Come along and follow me backstage through these photos. They were all shot in Saint-Ouen l’Aumône, in the Val d’Oise, a département northwest of Paris, which has been the only manufacturing site since the 1970s. The enameling process, which requires specialized ovens, is the only step outsourced to a partner based in Strasbourg.

Each range is made to order for a given customer, and the purchase order follows the range throughout production, so that each craftsman knows whom they are working for, and where on the planet the range will be shipped and installed once finished.

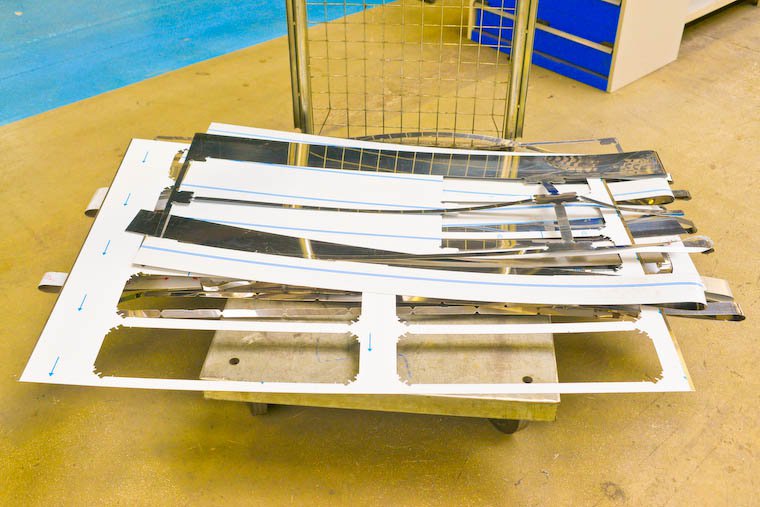

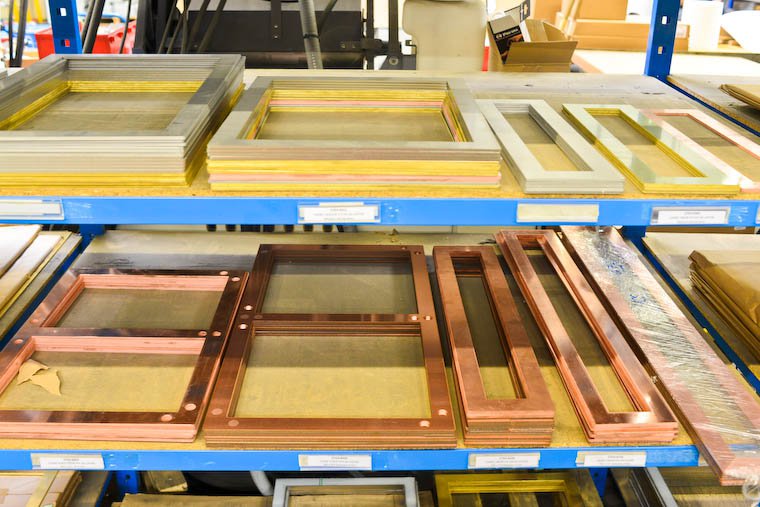

Everything starts with the thick metal plates that the range will be made of, based on the customer’s preference: stainless steel or copper. The stove’s structure, but also every screw, every welding, will be made from the chosen material.

This punching machine is used to cut out the various parts that make up the stove.

The punched parts.

Here are the “hollowed out” sheets that have been punched.

This is a folding machine to fold the sheets of metal. The use of machinery at La Cornue aims at making the craftsmen’s work less strenuous, without replacing their know-how. Here, the craftsman is inserting the parts that need bending, and adjusts the pressure depending on the required result.

The frame of the range is taking shape.

The La Cornue logo is “punched” into the metal.

The company is looking to increase the number of women within its production team. Here is Sarah, who happens to be the best welder on the team.

Each welder has their own workstation outlined with curtains, so they can work without disturbing one another. Welding quality is paramount to a flawless enamelling.

The stoves are made from stainless steel or enameled copper, and each customer can choose the color of the enamel. French customers usually go for neutral colors, while foreigners often choose bolder, more colorful options!

The trims can be made from nickel, chrome, copper… and this sample helps visualize the result.

These “color palette” samples are sent to every La Cornue store or dealer around the world.

When the parts are back from enamelling in Alsace, they are examined closely to check the color against the sample, and check consistency of color among all the parts, so that the color of the stove is perfectly even.

Here are the trims that will be mounted on the range once all the parts are assembled.

The range is assembled “naked”, with all its technical elements: gas burner or induction cooktop, simmering hob and, of course, the exclusive vaulted oven (gas or electric), patented by La Cornue, which offers unparalleled heat circulation.

The “naked” range is then tested (power and gas supply) to make sure that everything is working perfectly.

The enameled parts and metal trims are then mounted on the stove.

The La Cornue logo will be engraved with a customized inscription as requested by the customer.

Gray looks great too!

La Cornue also creates complete kitchens, including counters, furnishings, etc. In that case, they are first assembled completely at the workshop, then dismantled, packaged, sent, reassembled and installed in the customer’s kitchen.

The very first vaulted oven models, over a century ago!

What about you?

Are you dreaming of a La Cornue range too?